Gyatk

Gyatk

Gyatk

Gyatk

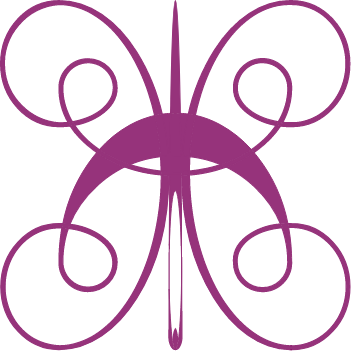

We assist you through the entire process for adopting RVCR technology products to help you attain ‘Zero Carbon’ objectives.

We assist you through the entire process for adopting RVCR technology products to help you attain ‘Zero Carbon’ objectives.

New Technology acquisition & streamlining it into mainstream business is a complex and demanding process. At GYATK, we understand the difficulties of new technology acquisition and its assimilation into existing business structure.

To help clients with this demanding challenge we have devised flexible mechanisms for joint assessments & evaluations for RVCR Product We offer multiple options for you to decide the best suited adoption methodology.

Any new technology acquisition starts with a business case built on assessment of technology suitability for your Product Range. we help you evaluate the value gain from RVCR technology with interactive assistance to your management / technical teams.

The business case analyses both tangible as well as intangible gains. The stage-wise assessment modules are listed below.

It starts with high level overview of a particular application The implications are evaluated in its entirety and include its technological, financial, economic, social, environmental and the perceptual value (under the heads listed below) and finer details are worked downwards

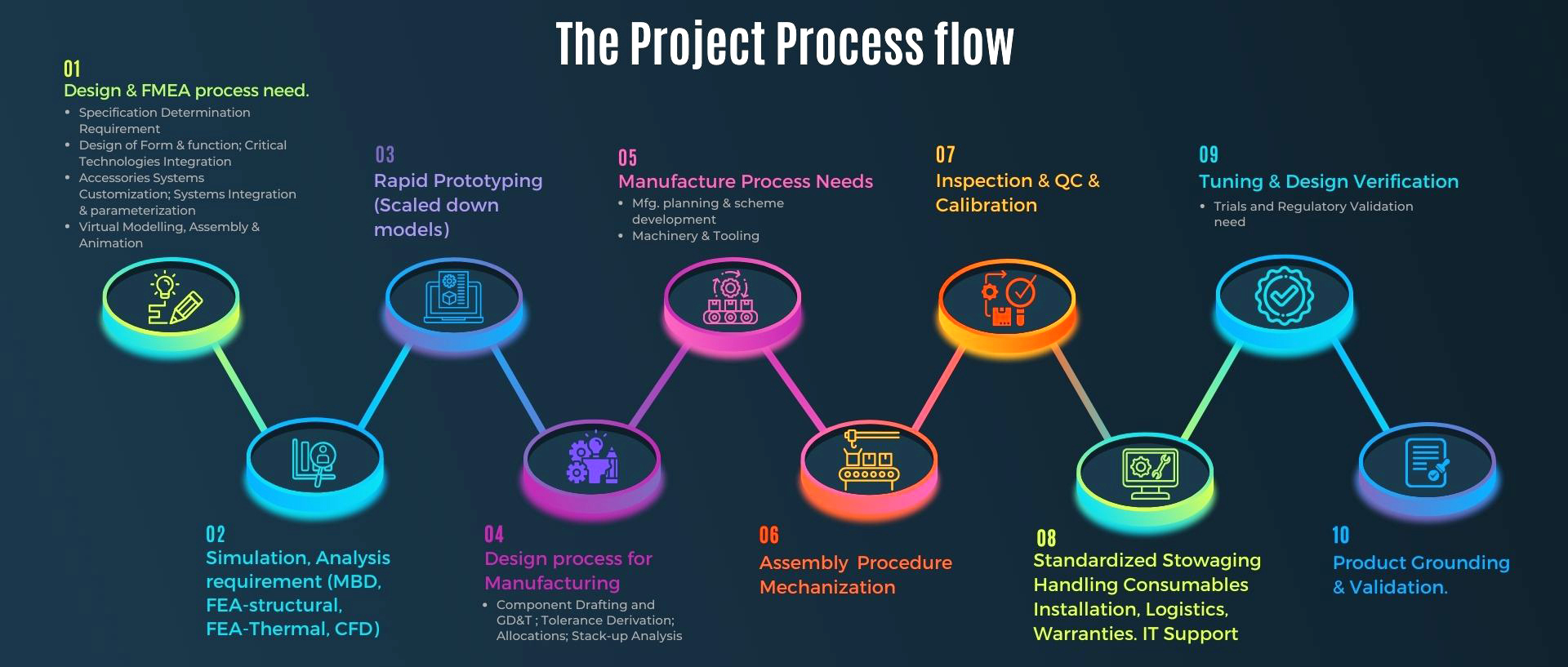

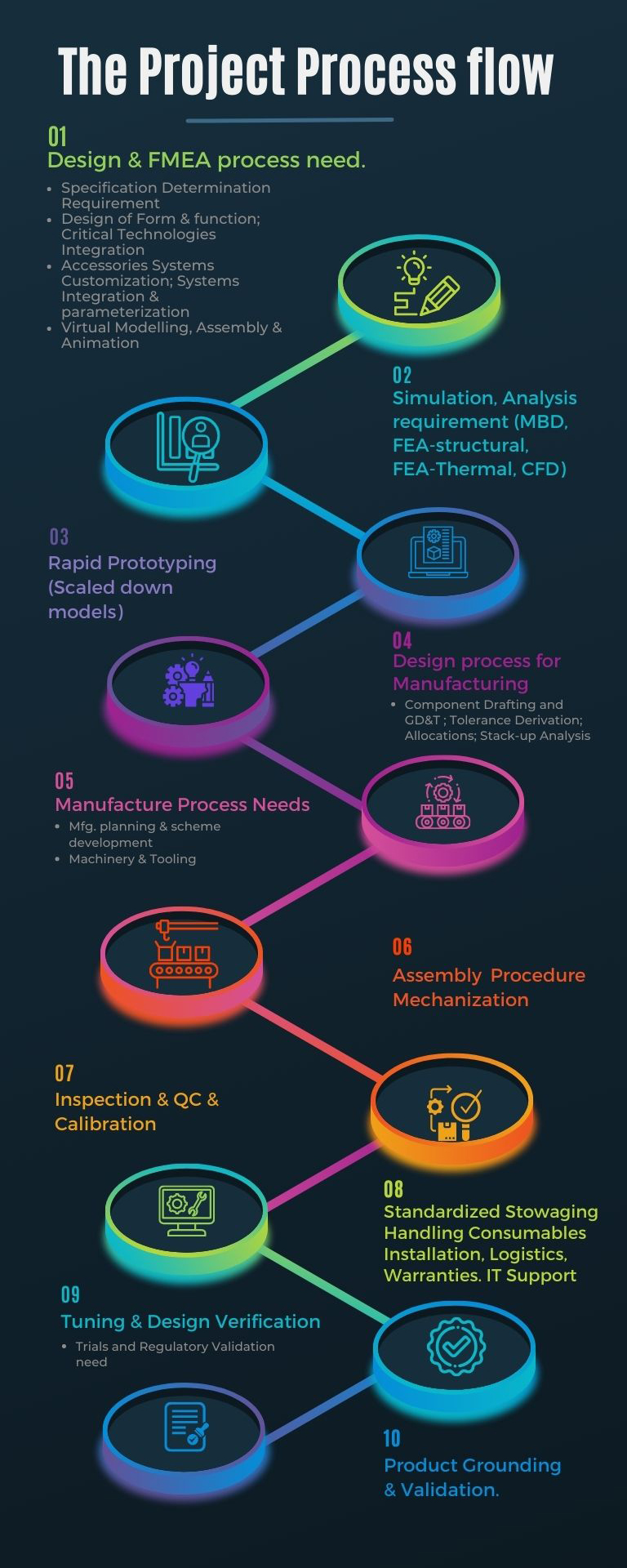

The product development is an high end engineering expertise. We take you thru the entire

RVCR Product Development project process

We evaluate its cost and other resource requirement.

Product Development planning and management

The RVCR concept is an invention in the field of kinematic mechanism that seeds a new breed of highly energy efficient machines with possibilities of newer functionalities to effectively deal with 21st century market drivers.